ECOEiT

|

No electric power needed

The air-driven design eliminates necessity for electric power supply. Introduction / operation of ECO EIT does not disturb the plant operation at all. |

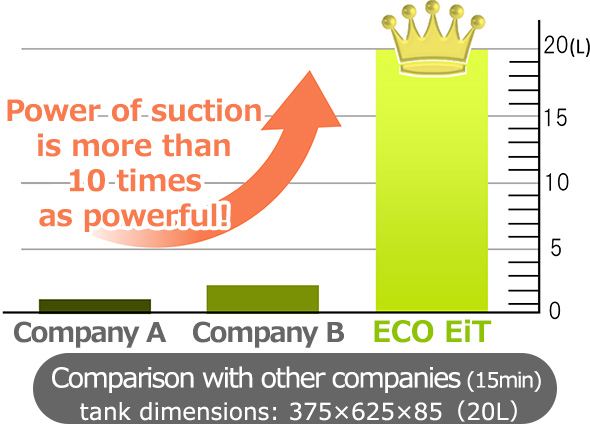

High recovery rate / strong suction system

The suction power ECO EIT achieves is surprisingly stronger than any of existing products. |

Little running cost

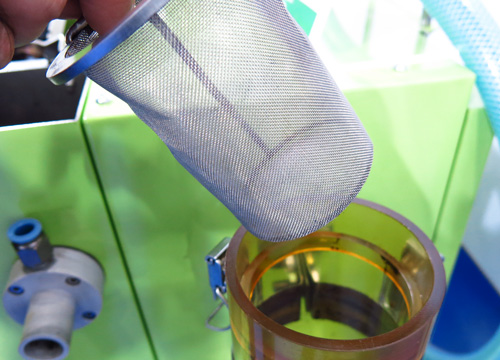

Adopt S-stainless filter which is not consumable leading cost of Zero. |

|

Easy to install/operate

Simple design to enable ease in operation. Easy to maintain too! |

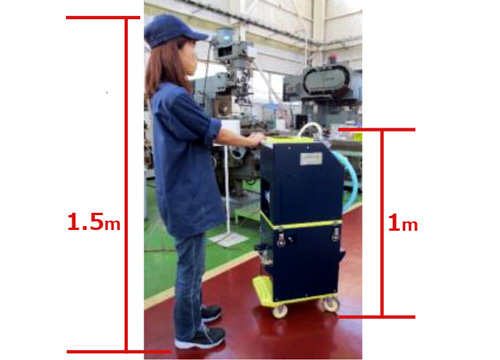

Free to move around on site

Compact with casters can wheel easily. One unit can be used for multiple machines as well. |

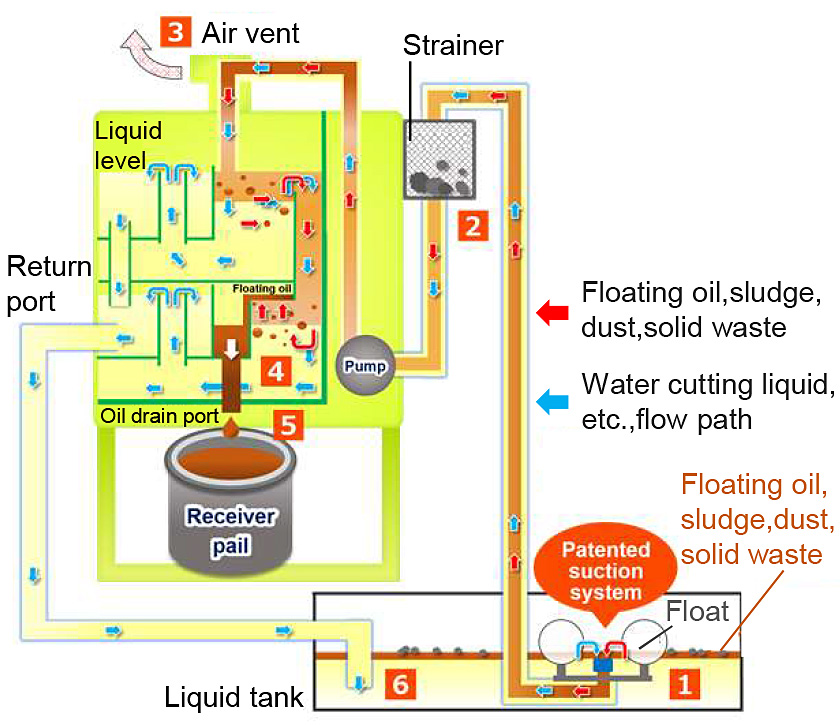

Collect floating oil only

Only floating oil stowed into pail can going through hose by Two-stage liquid level tracking system.*Eishin Patent registered |

Sun-up

We manufacture, sell and provide after service for distillation plant, which can treat highly-concentrated wasted water such as coolant water, heavy metal water, pigment water, alkaline water etc. We design the most suitable specification to fit with customer’s production process and layout. We also conduct periodic maintenance for customer to optimize operational cost.

Product・Technology

Our distillation system enable us to reduce processing load and cost for wasted water treatment. Moreover, we can reuse recovered water for production process through combining membrane unit.

Rock-D

Vacuum Distillation Unit

Solidify highly-concentrated

wasted water

Rock-E

MVR Unit

Reduce huge volume of

wasted water

Rock-Es

Small MVR Unit

Reduce small-mid volume of

wasted water

Extremely low running cost

MVR?

Mechanical Vapor Recompression

Temperature of steam should be increased when it’s compressed.

MVR is the technology reusing steam as heating-source, which is generated from wasted water by compressor.

This technology enables us to operate the system at very low running cost as it can utilize the latent heat of vaporization.

Solution